Fasteners and Machining: Maximizing Style for Superior Manufacturing

Browsing the World of Fasteners and Machining: Techniques for Accuracy and Rate

In the detailed realm of bolts and machining, the mission for accuracy and rate is a perpetual obstacle that requires precise interest to information and tactical planning. From recognizing the varied array of fastener types to selecting ideal products that can endure rigorous demands, each action in the procedure plays a crucial function in attaining the wanted end result. Accuracy machining strategies further boost the intricacy of this craft, needing a fragile balance between technical competence and cutting-edge methods. As we dive right into the methods that can improve both rate and efficiency in this domain, the interaction in between high quality control measures and operational quality becomes an essential focal factor.

Understanding Fastener Kind

When picking fasteners for a project, comprehending the numerous types available is important for guaranteeing optimal performance and integrity. Bolts can be found in a vast array of types, each developed for specific applications and needs. Screws are used with nuts to hold materials with each other, while screws are flexible bolts that can be made use of with or without a nut, relying on the application. Nuts, on the other hand, are inside threaded bolts that friend with screws or bolts, offering a safe hold. Washing machines are vital for distributing the lots of the fastener and stopping damages to the product being attached. Furthermore, rivets are permanent fasteners that are perfect for applications where disassembly is not needed. Recognizing the distinctions between these fastener types is important for choosing the right one for the job, ensuring that the connection is strong, resilient, and dependable. By picking the proper fastener kind, you can optimize the efficiency and durability of your project - Fasteners and Machining.

Picking the Right Materials

Recognizing the importance of choosing the best products is extremely important in ensuring the optimal efficiency and reliability of the chosen fastener kinds discussed formerly. When it pertains to fasteners and machining applications, the material option plays a critical function in figuring out the general toughness, longevity, rust resistance, and compatibility with the intended environment. Different materials offer differing residential or commercial properties that can substantially influence the performance of the bolts.

Common products made use of for bolts consist of steel, stainless-steel, titanium, brass, and aluminum, each having its distinct toughness and weaknesses. Steel is renowned for its high strength and toughness, making it suitable for a variety of applications. Stainless steel offers exceptional corrosion resistance, perfect for settings vulnerable to moisture and chemicals. Aluminum is corrosion-resistant and lightweight, making it appropriate for applications where weight decrease is important. Brass is usually picked for its visual allure and exceptional conductivity. Titanium is recognized for its extraordinary strength-to-weight ratio, making it excellent for high-performance applications. Choosing the appropriate material includes thinking about variables such as stamina demands, ecological conditions, and spending plan constraints to make certain the wanted performance and long life of the bolts.

Accuracy Machining Techniques

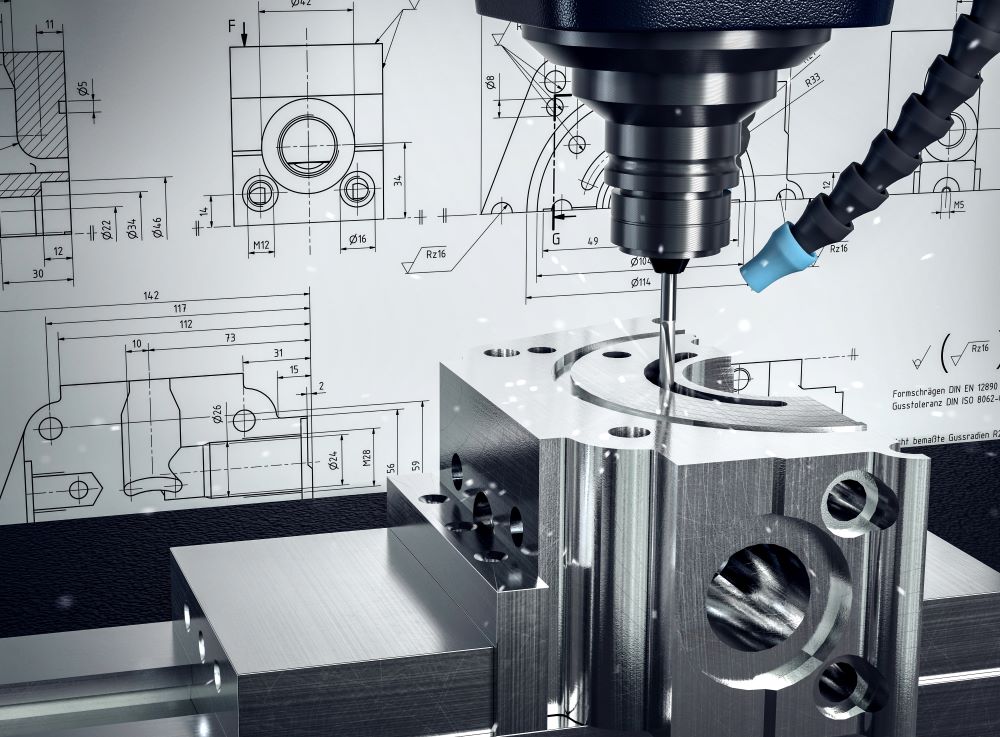

Along with CNC machining, other accuracy methods like grinding, transforming, milling, and exploration play important duties in fastener production. Grinding assists attain fine surface area finishes and limited dimensional tolerances, while transforming is frequently used to create cylindrical elements with accurate sizes. Milling and drilling procedures are vital for forming and developing openings in fasteners, ensuring they satisfy precise specs and feature properly.

Enhancing Speed and Efficiency

To maximize bolt manufacturing procedures, it is necessary to simplify operations and implement efficient techniques that match accuracy machining strategies. Automated systems can take care of repetitive tasks with accuracy and speed, allowing employees to focus on even more facility and value-added activities. By integrating these techniques, suppliers can achieve a balance between rate and precision, eventually enhancing their affordable side in the bolt industry.

Quality Assurance Procedures

Implementing rigorous quality control procedures is crucial in making sure the reliability and uniformity of fastener products in the manufacturing process. Fasteners and Machining. Quality control steps encompass numerous stages, starting from the option of raw products to the final examination of the finished bolts. This entails analyzing elements such as material composition, durability, and strength to assure that the bolts fulfill industry criteria.

Regular calibration of equipment and machinery is necessary to preserve consistency in manufacturing and make certain that bolts satisfy the necessary tolerances. Carrying out rigorous protocols for determining and attending to issues or non-conformities is vital in avoiding click to find out more substandard products from entering the market. By establishing a comprehensive quality assurance structure, manufacturers can maintain the reputation of their brand name and deliver bolts that meet the highest possible standards of efficiency and resilience.

Verdict

In the intricate world of fasteners and machining, the mission for precision and rate is a perpetual challenge that demands precise attention to information and critical planning. When it comes to bolts and machining applications, the material selection plays a crucial duty in figuring out the total toughness, longevity, deterioration resistance, and compatibility with the designated atmosphere. Accuracy machining entails numerous sophisticated approaches that ensure the limited resistances and specifications needed for fasteners.In addition to CNC machining, other accuracy methods like grinding, turning, milling, and exploration play essential functions in fastener production.To maximize fastener production processes, it is vital to enhance operations and execute efficient strategies that enhance precision machining strategies.